- Civil Lab Mechanical Lab Engineering Lab Equipments

- sales@didacticlabequipments.com

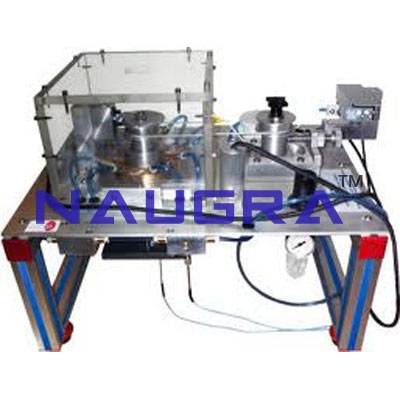

CAT NO: DIDACTICNLE-Export-205109

EXERCISES AND PRACTICAL POSSIBILITIES

Some Practical Possibilities of the Unit:

1.-Visual examination of a small reaction turbine.

2.-Production of torque/speed and power/speed curves.

3.-Evaluation of specific air consumption at a range of speeds and pressures.

4.-Application of the First Law to a simple open system undergoing a steady flow pressure.

5.-Determination

of the isentropic efficiency of a reaction turbine and plotting the end

states on a temperature/entropy diagram.

6.-Construction of

retardation curve and the determination of resisting torques due to

bearing friction, disc friction and windage, at different speeds.

7.-Obtaining

the inlet pressure effect on the outlet power and effectiveness of the

turbine, as well as torque, speed and power curves.

Other possible practices:

8.-Sensors calibration.

Practices to be done by PLC Module (PLC-PI)+PLC Control Software:

9.-Control of the HTRC unit process through the control interface box without computer.

10.-Visualization of all the sensors values used in HTRC unit process.

11.-Calibration of all sensors included in HTRC unit process.

12.-Hand on of all the actuators involved in the HTRC unit process.

13.-Realization

of different experiments, in automatic way, without having in front the

unit. (This experiment can be decided previously).

14.-Simulation

of outside actions, in the cases do not exist hardware elements

(Example: test of complementary tanks, complementary industrial

environment to the process to be studied, etc).

15.-PLC hardware general use and manipulation.

16.-PLC process application for the HTRC unit.

17.-PLC structure.

18.-PLC inputs and outputs configuration.

19.-PLC configuration possibilities.

20.-PLC program languages.

21.-PLC different programming standard languages.

22.-New configuration and development of new process.

23.-Hand on an established process.

24.-To visualize and see the results and to make comparisons with the HTRC unit process.

25.-Possibility of creating new process in relation with the HTRC unit.

26.-PLC Programming Exercises.

27.-Own PLC applications in accordance with teacher and student requirements. Fluid Mechanics Lab Equipments manufacturers.